Arnold Wragg Ltd

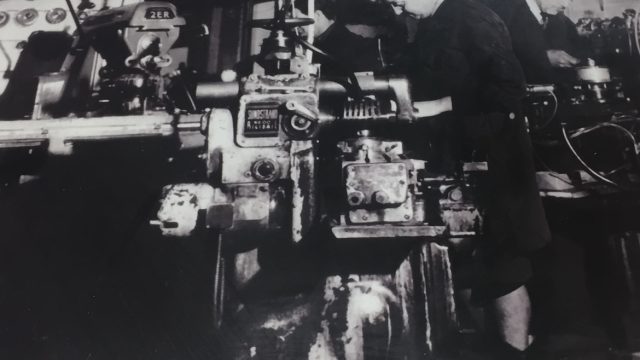

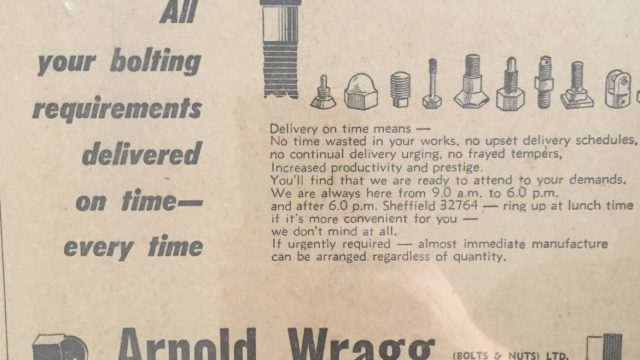

Pioneering Precision in Fastener Manufacturing. With over half a century's expertise and AS9100 accreditation, we're your trusted partner in engineering excellence.

Our Values

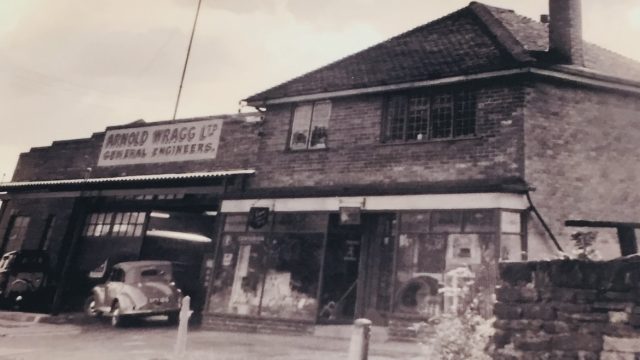

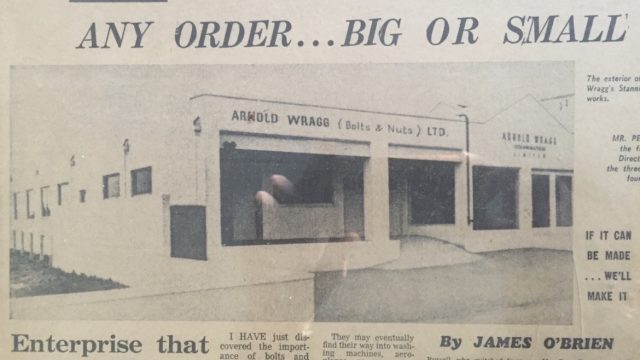

From Sheffield, to the world

Rooted in Sheffield's rich industrial heritage, Arnold Wragg Ltd extends its reach globally, delivering high-performance fasteners and components to the most demanding industries. Our expertise in advanced materials and stringent production standards has solidified our reputation as a leader in fastener manufacturing.